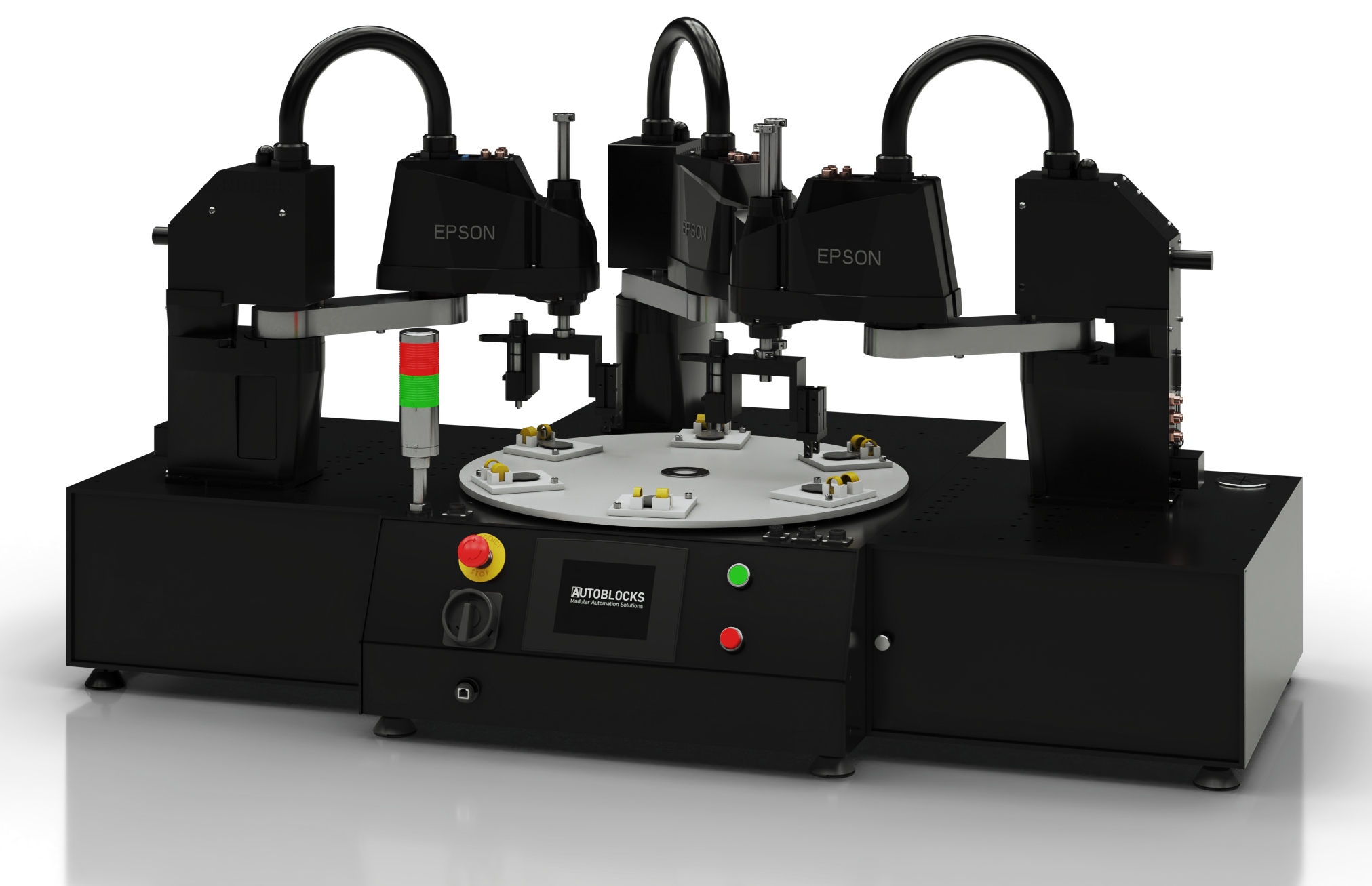

Overview

AutoBlocks™ revolutionizes the world of custom machine builds by introducing a standardized approach, effectively minimizing costs and mitigating risks associated with constructing automated systems. Our innovative methodology involves a meticulous step-by-step process that empowers our team of expert engineers to concentrate on strategic customization aspects, such as fixtures, grippers, and other essential end-of-arm tooling. As a result, the machines we deliver adhere to the highly efficient 80/20 rule—80% standardized and 20% tailored to your specific needs.

By embracing this controlled and structured approach, we ensure a predictable and transparent development process that fosters trust among our clients. The predictability of our methodology enables the creation of machines that are not only reliable but also repeatable, scalable, and remarkably easy to support. With AutoBlocks™, you can expect consistent and top-notch performance from your machines, while enjoying the peace of mind that comes with a streamlined and optimized manufacturing process.