Product Description

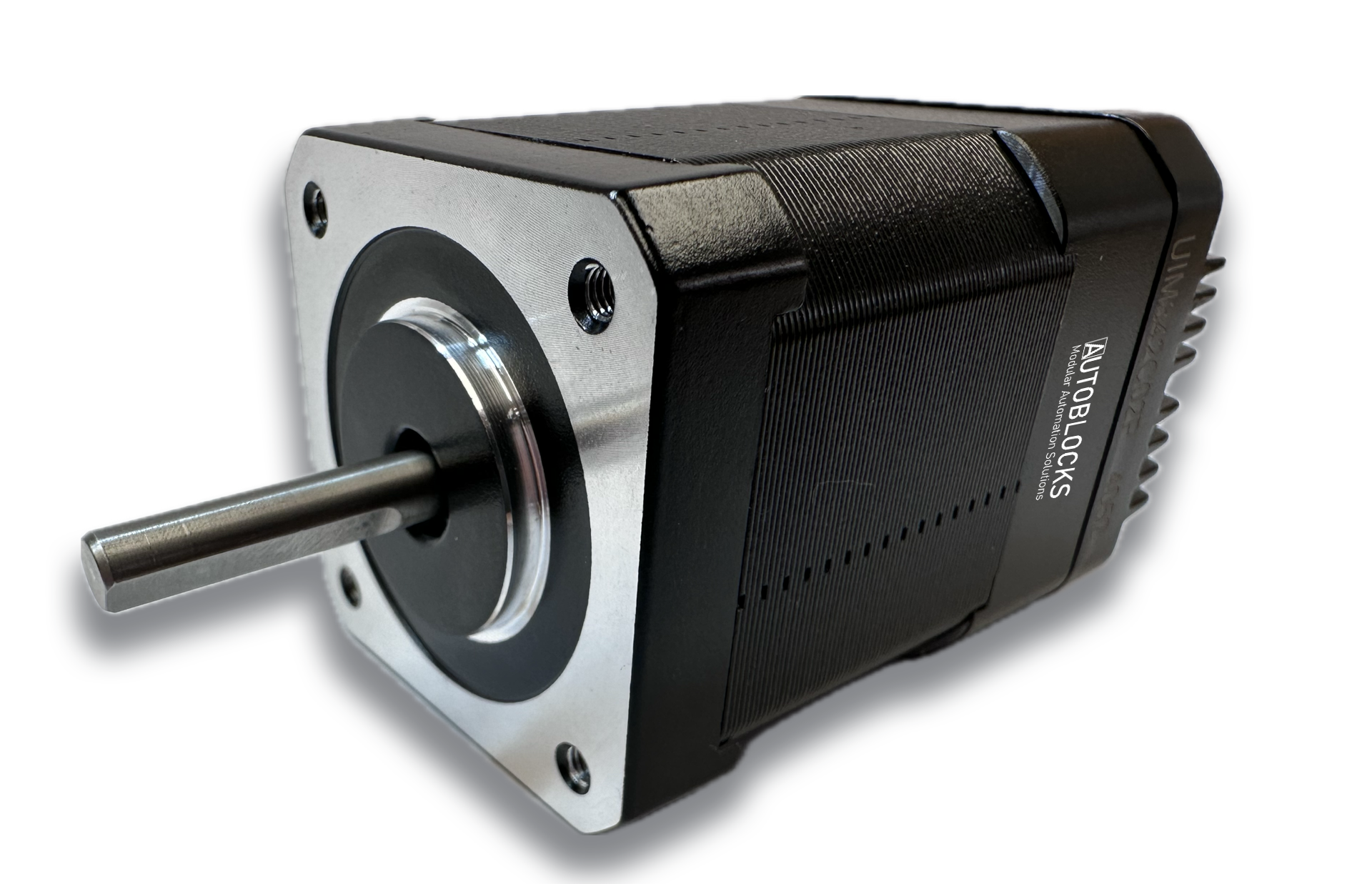

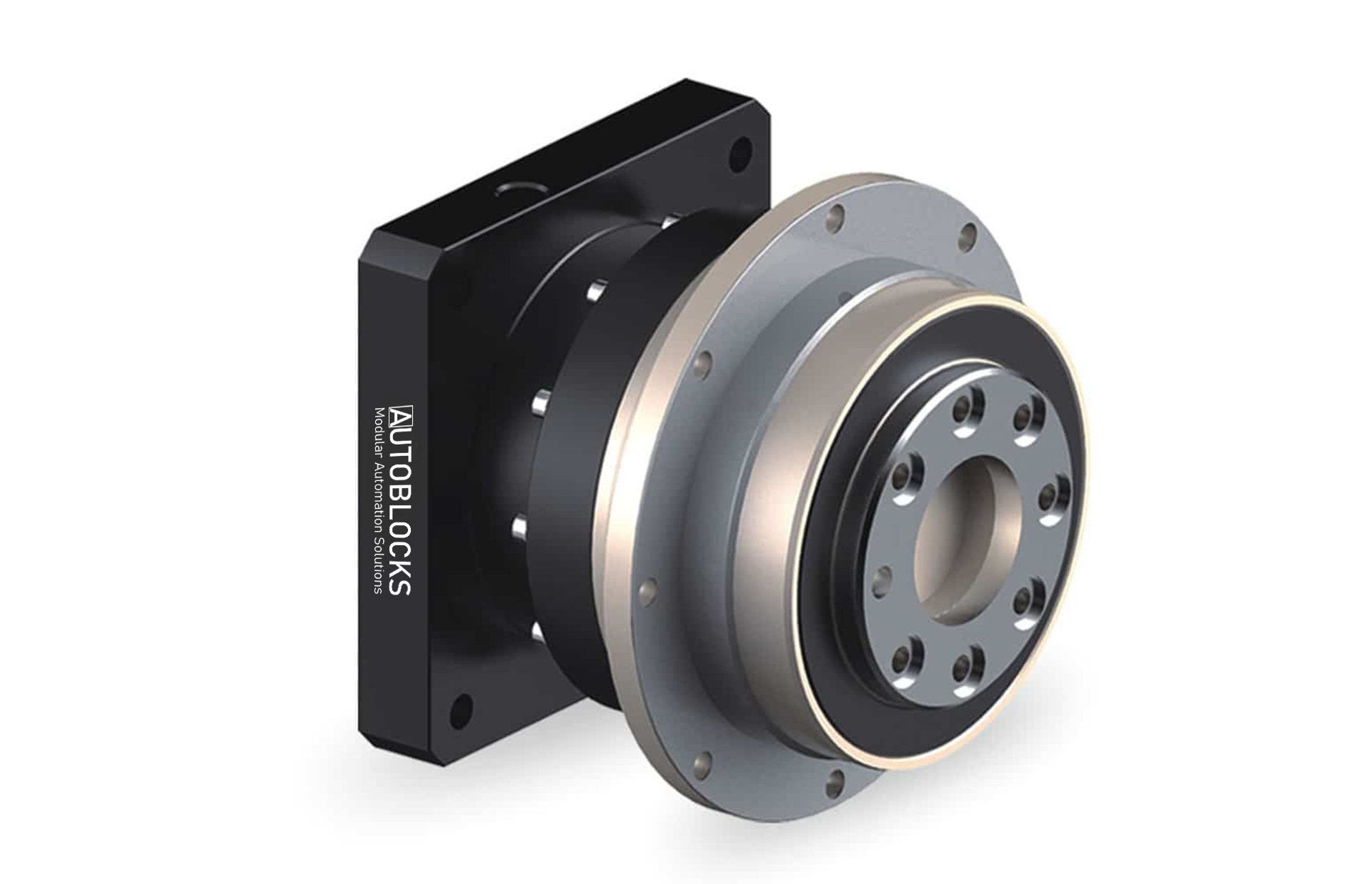

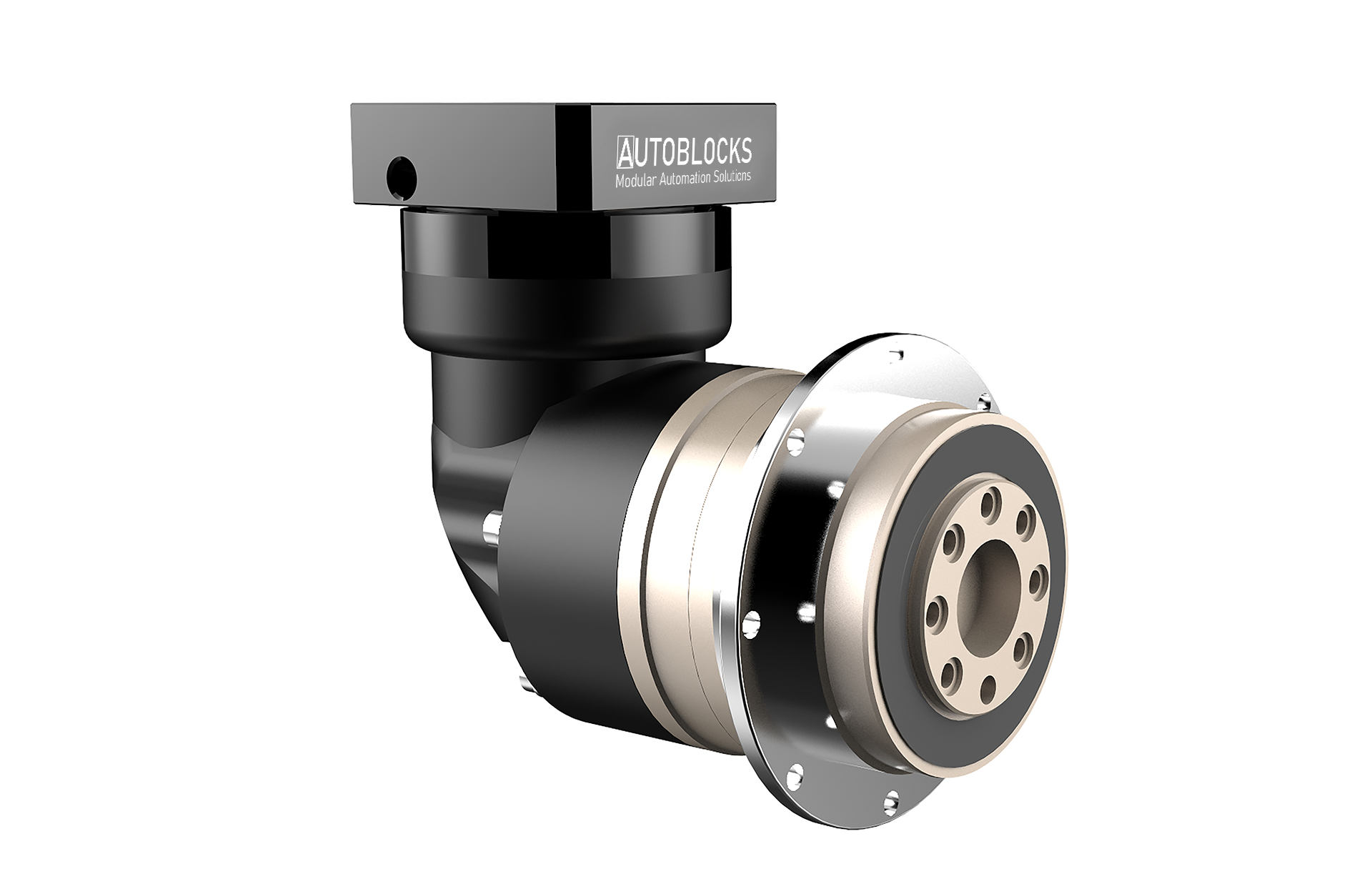

Custom Turn Block indexing control boxes are available in unlimited sizes. Thes custom built Turn Blocks feature the same non-code integration architecture and software as all the other Turn Blocks but built with custom size indexing motors and drives. These configurations can be built with any industry leading gear box up to any size, with hollow core or other customized features. Contact AutoBlocks sales for you custom configuration.

Features:

• No code integration.

• Control up to 8 stations with plug and play apps.

• Free user defined function blocks for custom app development.

• Select Program direction, speed, acceleration, deceleration, and # of positions.

• UL/CE horizontal control panel controls power, air, communication & safety.

• Touch Screen 7” HMI and PLC with Ethernet IP, Modbus, digital I/O, 0-10V analogue communications.

• Includes machine network switch, 24V power supply, safety relay, main/branch circuit breakers.

• Safety light curtains, door switches, part presence, and light tower plug and play with standard metric connections.

• Epson Robots are plug & play.

• SMC pneumatics are plug and play.

• Machine base expandable and reconfigurable with modular block structure.

• Process data capture

• Standard and custom table options from aluminum, steel, and engineering plastics.

• Bar code recipe selection

• Easily mount enclosures to directly to the block.

• Custom precision CAM driven, planetary, strain wave, or other zero back lash gear boxes.

*Recommended for assembly automation of with two or more steps. Offers maximum flexibility with the ability to redeploy and scale with volume.

SPECIFICATIONS

• 48” Diameter table.

• 5 Arc Min backlash maximum standard.

• 3 Arc Min backlash upgrade optional.

• Symmetrical vertical load maximum 25 lbs. [11Kg].

• Asymmetrical unbalanced vertical load maximum 12 lbs. [5.4Kg].

• Standard tables with tapped hole grids available in 3/4″ thick Acrylic, and ¼” Aluminum.

• Custom table materials available including ESD safe options.

• Prewired for light curtains with built in safety relay.

• Prewired for safety enclosure door switches.

• Prewired for part presence sensor including detection beam with programable distance.

• E-stop equipped with safety I/O to control other blocks from same E-Stop button.

• Prewired for 3 color light tower to indicate machine state.

• Modbus TCP configured for Universal Robots and Epson T series scara robots.

• Station Connections (3 stations per table: 240/1/60-volt 5 amp power, 80 PSI air, (8) I/O, and Modbus TCP.

• Weight: Weight: 175 lbs. not including the table/parts/fixtures/enclosure.

• Voltage: 240 VAC

• Phase: 1 PH

• Frequency: 60 HZ

• Full Load Current: 18.82 AMPS

• Largest Motor Load: 6.1 AMPS

• Feeder Protection: 20 AMPS

• SCCR Rating: 10 kA rms SYMM, 240V MAX

• Environment Rating: TYPE 1

• Maximum Table Speed: 20 RPM

• Max Torque at Max Speed: 5.4 in-lbs

Software Logic:

• Start/Stop trigger options include remote, foot pedal, start/stop buttons, and timer.

• Configured as a master to coordinate other machine blocks based on hierarchical handshake with each machine block. The operator initiates indexing based on start trigger. Indexing proceeds only if all machine block processes are complete, and the operator has completed the operator load/unload cycle.

• The auto indexing mode automatically indexes based on a programmable timer subject to the same hierarchical handshake with the machine blocks. If the operator cannot keep up with the timer the machine flips back to the manual trigger mode.

• When the machine is configured with a light curtain, and set to automatically index, the braking action of the light curtain pauses the indexing until the light curtain is unbroken.

• Each machine block can trigger machine faults based on a programmable timer or robot faults.

• Part presence sensing detects when a part is unloaded and loaded using a programable distance trigger. The triggers are programmed to detect the top of a loaded part and the bottom of the unloaded fixture. During the load/unload cycle the sensor must cycle through a presence, absence, presence before the table is cleared to cycle. At the end of a production run the operator presses the empty button and the machine is allowed to continue running a complete rotation skipping process steps when parts are not present.

• With the part presence sensor, the machine tracks parts through each table rotation. Machine process steps skip empty nests.

• Robot Block waypoints are programmed on the robot including fault modes, local sensors, and EOAT triggers. Errors are reported to the Turn Block controller and displayed on the table HMI and indicated on the light tower.

SPECIFICATIONS

• 48” Diameter table.

• 5 Arc Min backlash maximum standard.

• 3 Arc Min backlash upgrade optional.

• Symmetrical vertical load maximum 25 lbs. [11Kg].

• Asymmetrical unbalanced vertical load maximum 12 lbs. [5.4Kg].

• Standard tables with tapped hole grids available in 3/4″ thick Acrylic, and ¼” Aluminum.

• Custom table materials available including ESD safe options.

• Prewired for light curtains with built in safety relay.

• Prewired for safety enclosure door switches.

• Prewired for part presence sensor including detection beam with programable distance.

• E-stop equipped with safety I/O to control other blocks from same E-Stop button.

• Prewired for 3 color light tower to indicate machine state.

• Modbus TCP configured for Universal Robots and Epson T series scara robots.

• Station Connections (3 stations per table: 240/1/60-volt 5 amp power, 80 PSI air, (8) I/O, and Modbus TCP.

• Weight: Weight: 175 lbs. not including the table/parts/fixtures/enclosure.

• Voltage: 240 VAC

• Phase: 1 PH

• Frequency: 60 HZ

• Full Load Current: 18.82 AMPS

• Largest Motor Load: 6.1 AMPS

• Feeder Protection: 20 AMPS

• SCCR Rating: 10 kA rms SYMM, 240V MAX

• Environment Rating: TYPE 1

• Maximum Table Speed: 20 RPM

• Max Torque at Max Speed: 5.4 in-lbs

Software Logic:

• Start/Stop trigger options include remote, foot pedal, start/stop buttons, and timer.

• Configured as a master to coordinate other machine blocks based on hierarchical handshake with each machine block. The operator initiates indexing based on start trigger. Indexing proceeds only if all machine block processes are complete, and the operator has completed the operator load/unload cycle.

• The auto indexing mode automatically indexes based on a programmable timer subject to the same hierarchical handshake with the machine blocks. If the operator cannot keep up with the timer the machine flips back to the manual trigger mode.

• When the machine is configured with a light curtain, and set to automatically index, the braking action of the light curtain pauses the indexing until the light curtain is unbroken.

• Each machine block can trigger machine faults based on a programmable timer or robot faults.

• Part presence sensing detects when a part is unloaded and loaded using a programable distance trigger. The triggers are programmed to detect the top of a loaded part and the bottom of the unloaded fixture. During the load/unload cycle the sensor must cycle through a presence, absence, presence before the table is cleared to cycle. At the end of a production run the operator presses the empty button and the machine is allowed to continue running a complete rotation skipping process steps when parts are not present.

• With the part presence sensor, the machine tracks parts through each table rotation. Machine process steps skip empty nests.

• Robot Block waypoints are programmed on the robot including fault modes, local sensors, and EOAT triggers. Errors are reported to the Turn Block controller and displayed on the table HMI and indicated on the light tower.

Turn Block Manual

Turn Block Manual