Overview

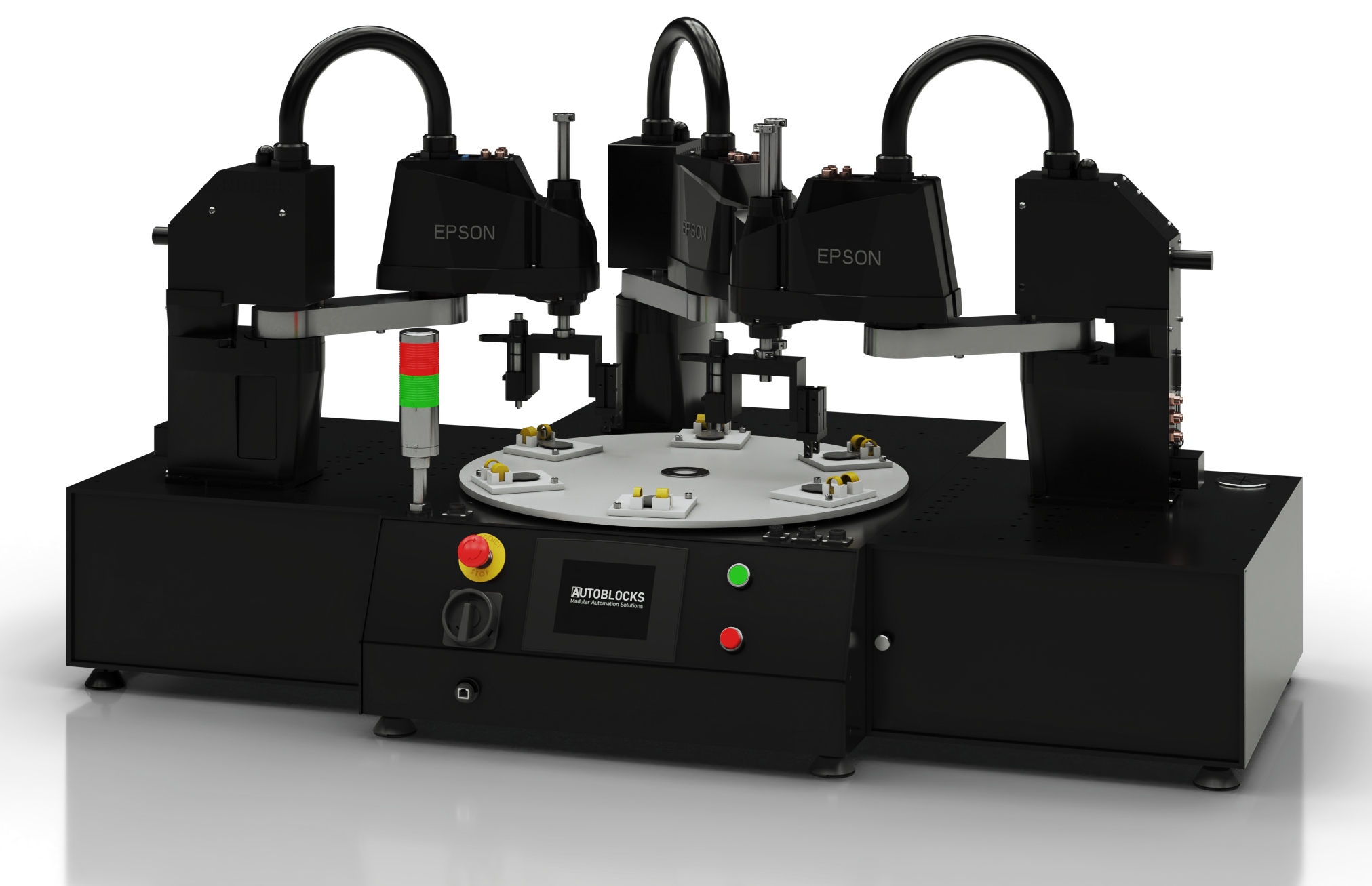

Autoblocks offers a comprehensive suite of automation solutions aimed at simplifying and optimizing industrial processes. The cornerstone of the product line is the Autoblocks Control Block, a powerful and unified machine controller that integrates logic, safety, and motion control into a single platform. Supporting up to 6 axes of motion, the Control Block is designed for no-code integration and allows easy control of robots, vision systems, safety devices, and sensors. This system is ideal for precision assembly and is scalable from small batch processes to full production lines.

Complementing the Control Block is the AB+ product range, which includes a variety of motors, actuators, and precision planetary gearboxes. These components provide plug-and-play functionality, precise control, and flexibility, ensuring seamless integration across various automation systems. Whether for gantry or SCARA robots or custom configurations, Autoblocks provides a configurable, scalable, and cost-effective solution for integrators and machine builders in industries like automotive, electronics, and medical devices.